Kiln Burners

- Pulverized coal firing along with all combinations of liquid/gaseous fuels

- Capability to work on 100% pulverized coal without support fuel or with minimum supporting fuel during normal conditions

- Utilization of Low Calorific Value (LCV) Gases like Producer Gas, Coal Gas

- Associated process automation for increased safety & efficiency

- Design, Metallurgy and Engineering customized on process data and temperature profiling to optimize cost and increase efficiency

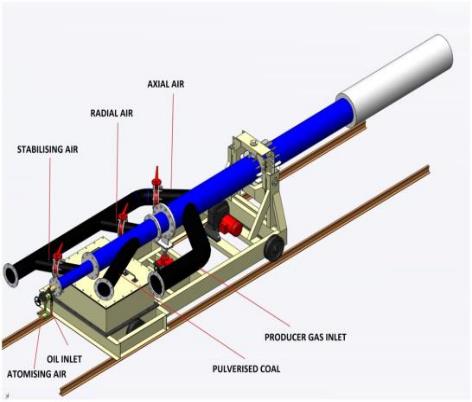

Multi Channel Kiln Burner With Trolley

Salient features:

- Burner components are designed to ensure longer life.

- Higher turn down ratios achievable.

Fuels fired in burner are:

- Solid Fuels: Pulverized Coal

- Gaseous Fuels: Low CV Gases (Producer Gas/Coal Gas/BF Gas/Coke Oven Gas/CBM Gas), High CV Gases (Propane/LPG /Natural Gas)

- Liquid fuels: HFO, LDO, HSD, LSHS, and any grade of liquid fuel.

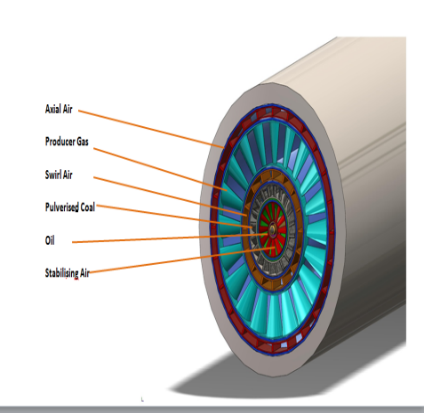

Nozzle Design

Features:

- Swirl Vane design for optimum Flame Momentum

- Design for Radiant Diffusion Flame

- Entrainment of secondary air into primary air for turbulent, strong and narrow flame

- High Flame Temperature by minimum excess air

- High Kiln speed and reduced residence time in burning zone

- Optimum degree of internal re-circulation

- Ignition time and burnout time as per the required flame shape.