Industrial Waste to Energy

- Completely customized turnkey solutions for incinerating waste products and converting into steam/energy

- Design/manufacture of thermal oxidizers/thermal combustors for incinerating waste effluents from various manufacturing processes

- Addition of WHRBs to convert the latent heat of the flue gases generated from the oxidation/reduction process into usable energy

- Helps companies meet mandatory requirements of “Zero Liquid Discharge”

- Retrofitting and modernization of existing waste disposal system to recover heat and energy

- Possible usage and retrofitting of spare boilers for converting waste energy into usable heat

Advantages of Incineration

- Industrial Waste Management

- Reduce Volume

- Economic Viability

- Elimination of Toxicity

- Substitute for Fossil Fuel

- Decomposition of Organic waste

- Comply to Environment Norms

Energy from Industrial Waste depends on

- Chemical composition

- Local price of petroleum fuel

- Waste Conditioning

- Available Support Fuel

- Emission Control norms

- Energy from waste

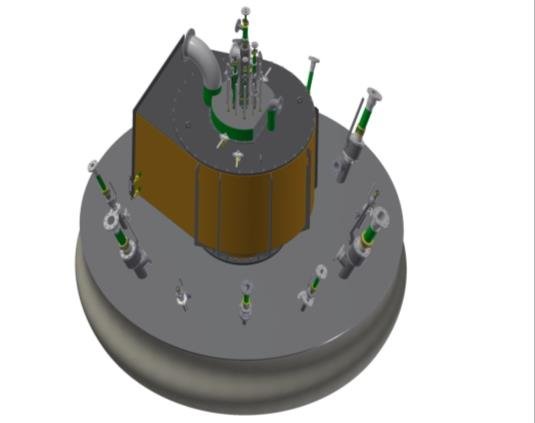

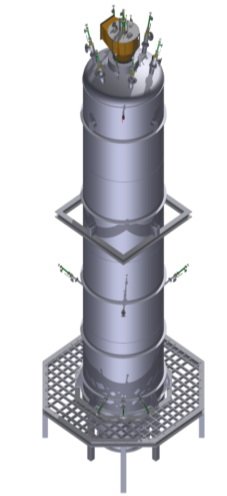

Liquid Waste Incineration

- Top down firing

- Salty, chlorinated and flour containing waste liquids

- Vertical firing

- Acids from production streams.

- 42 different waste liquids

- 10 different Off-Gas Streams